100 Words

The aim of my project is to open the user’s eyes to the nation’s throw-away nature. I have been developing zero waste packaging with a secondary function so that everything can either be 100% recycled, or re-used. This project is specifically tailored for laptop packaging and performs as a laptop stand in its second function. The laptop is protected by an all-natural substance grown from mycelium (mushroom fibres) and agricultural by-product (wood chippings). The mycelium acts like a glue growing throughout the wood chippings bonding the mix together to create a spongy substrate similar to Styrofoam while being 100% biodegradable.

Critical Review

After working on this project for 8 long months, experiencing its highs and lows, successes and failures, I want to look back and make sure that the message I set out to convey at the very beginning is still legible now.

My aim for this project was to raise the awareness of how important the full life cycle of products and their materials are to the planet. I wanted to help consumers realise that not everything had to be thrown into a landfill, but could be composted, recycled or reused. My early research showed me how much is possible through recycling and what type of products can be created with it, this is what gave me my inspiration to explore the huge and always expanding industry of renewables.

Once I had spent some time looking into different areas of environmental design I narrowed my research down into waste, more specifically packaging waste. With over 4 million tonnes of packaging waste being added to landfills per year from the UK alone, it was clear to me that this was a great opportunity to make a difference through design. I wanted to find a way to package products without using any harmful materials or gases, without having any adverse effect on the products safety or security.

I gained a lot of inspiration for this project from the process of Slow Design and certain natural processes that can do a much better job than some manufacturing processes. I had got it into my head through researching natural materials that the best way to progress in my project would be to grow my own. During phase 1 I discovered how I would be able to do this, by growing mycelium throughout agricultural by product (in my case, wood chippings). I tried a few test samples to find out how the material compared to other manufactured options and also to work out the best growing conditions to gain the best possible outcome.

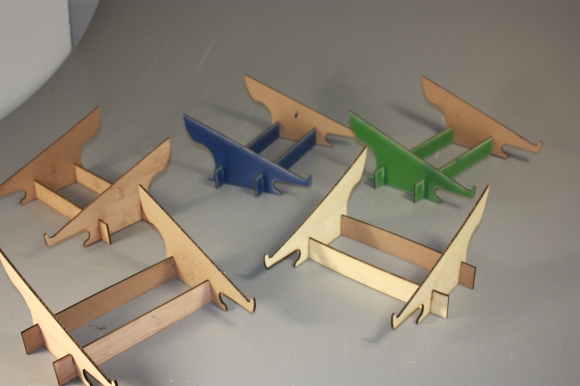

As well as recyclable, I wanted to make my packaging reusable. Before deciding on what it could be reused as, I first had to decide what I was going to be packaging… It had just so happened that one of my flatmates had a new laptop delivered during my research period, and cluttering the hallway outside his bedroom was of course a pile of useless plastics from the box. Not to say that his untidiness was the only thing directing my project, but I will admit that it did give me a push in that direction. Knowing that my project was taking shape and that I was focusing on laptops, I did some research on what people buy along with their laptop, what accessories they use, what accessories they wish they had and how they would use them. The highest demands seemed to be for cases, desk tidies and stands. From this, after testing a few concepts for each, I decided it would be best to create a stand from the packaging, as the early structures proved to be strong and simple to assemble. With other designers using them around the studio, I quickly refined my design and started to incorporate it into the packaging.

During Phase 2, I continued to work on and finalise my design language. I had always wanted to take a very minimalist approach to support the theme of only using what is needed to reduce waste. I took early inspiration from Muji, who produce a lot of environmentally friendly products with “no brand” style of branding. Muji have managed to appeal to a very specific demographic made up of those who are anti-corporate logo, design savvy and environmentally conscious. This demographic has been growing larger and larger each year and is the perfect audience for my marketing. I chose to stick to all natural colours in order not to contradict the meaning of the project; this involves the plane colour of the card, the natural bamboo veneer and the earthy crumbly texture of the foam.

Once I had finished the layout of packaging and had packed, unpacked, packed and unpacked repeatedly until the interactions were as smooth and simple as they could be, I was finally happy enough to move on to my 1 great image, one hundred words and one minute video which was surprisingly enjoyable to do and having the opportunity to try my hand at directing, filming and editing was a great experience. Looking back I feel as though I have created a packaging concept that is capable of showing the users the importance of and also the possibilities available through recycling.

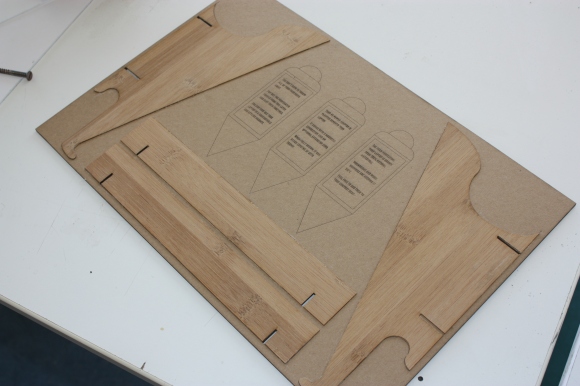

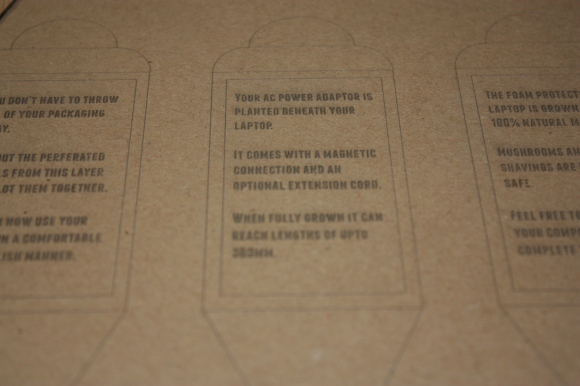

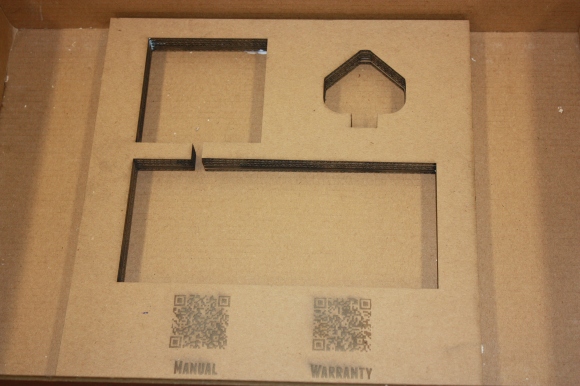

Box Templates

After trialing template after template for bases, lids and inserts to find the perfect fit, I eventually managed to refine the layout so that everything slots together neatly and more importantly unboxes easily. The base and inserts are made from double corriboard to offer support and the lid is cut from single corriboard to save materials and to allow it to slot in and out of position easily.

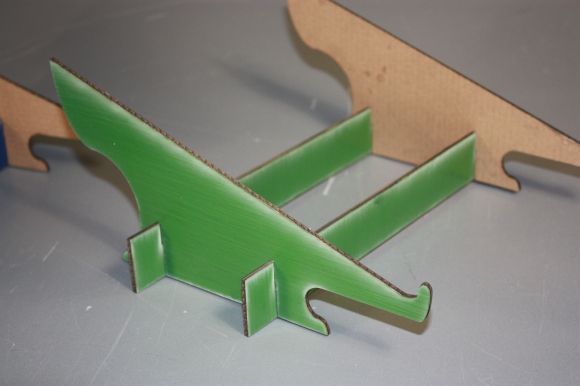

Complete Stand

After testing a few different veneers and adhesives, I finally settled on the Side Pressed Caramel Bamboo with AURO’s all purpose natural adhesive. I made the final cuts and assembled the stand this afternoon as well putting together the top panel for the packaging, both of which are displayed below.